Robotics isn’t just coming to construction, it’s already here.

That was the message from industry experts at the Power of Robotics in ��������ion education session held Jan. 24 at the World of Concrete conference in Las Vegas.

DPR ��������ion robotics lead Henning Roedel and Rogers-O’Brien ��������ion chief innovation officer Todd Wynne explained to attendees that use of robots in the construction industry is already underway with innovative products soon to arrive in the marketplace.

“We were really just trying to demystify that robots have been on our jobsites for years, whether it’s a tele-operated concrete pump or robotic total stations. We were trying to show that these are just tools but also showed real world examples of how we’ve been using modern tools,” Wynne said in an interview.

It opens up opportunities for those who have bodies that are no longer able to work in our industry,

— Henning Roedel

DPR ��������ion

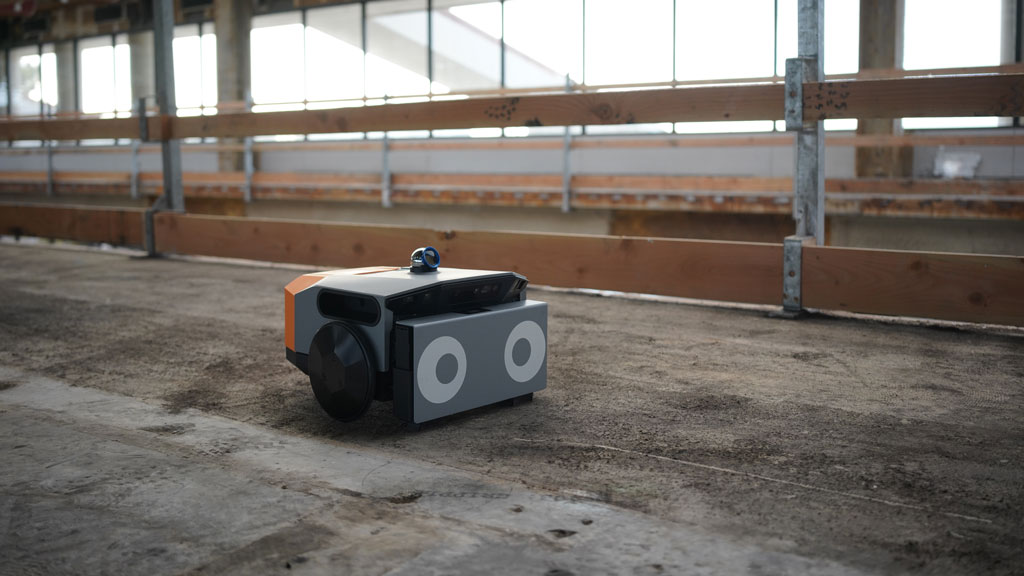

Some of these tools included layout printers, or as Wynne termed them, “a Roomba with a printer attached” that transfer BIM layouts directly to the construction floor more quickly and accurately than a human being.

“For the last decade we’ve been on the journey of trying to build from the model and connecting that BIM world with the world of operations. Having that interstitial layer of layout, survey and control ties the model space to the real world. Now we’re starting to see these robots leverage model files and even traditional field engineering techniques,” he said.

Roedel described the Hilti Jaibot, an onsite automated drill, capable of drilling holes into overhead concrete floors whether fluted deck, steel on metal deck or cast-in-place concrete.

“It does so accurately, safely and fast. We love it because it’s limiting exposure to dust, taking the burden off the shoulders of people in the field, and it’s making easier work for a single operator,” Roedel said.

He added using robotics on the worksite opens up the industry to new heavy equipment operators such as women and those with disabilities.

“Just because you’re in a wheelchair it doesn’t mean you can’t operate a robot,” he said.

Robotics also allows those with extensive experience to stay in the industry longer, Roedel said.

“It opens up opportunities for those who have bodies that are no longer able to work in our industry, but they still want to contribute,” he said.

“There’s so much asset knowledge our industry is losing that we can reignite in that way,” Wynne added.

New tools will also appeal to youths who don’t want to get dirty in the field but do want to use robots and other equipment, Wynne said.

“We need to exploit the innovations happening in our industry to attract those workers,” he said.

Roedel said while some worry about robots taking jobs or are uncomfortable with machines, the ongoing labour crunch makes adoption of new technologies essential.

“We’re in an industry and we’re in a time right now when we need these tools. Not only do we have a gap in productivity that’s persisted for decades, we’re facing a labour shortage. We can’t fill the jobs fast enough to build the work we need to support society,” he said.

“It really is the evolution of a power drill,” Wynne added. “It’s using ones and zeroes and doesn’t have any kind of sentience and can’t create its own objectives, it’s really just a modern tool. We don’t know how the computers in our pockets work, but we trust and use those every day.”

What I find most appalling about this article is the blatant lies about what the true reality these “innovations” mean to the construction industry. Namely the elimination of a human workforce, sure you can get people that don’t want to get dirty or (shamelessly) promote that it helps the disabled. However these people are going to be supervision, not working ,and they’ll be supervising machines that will be replacing hundreds if not thousands of real construction workers. Let’s not forget that robots don’t get paid, don’t get sick or tired (as long as they have batteries), never get overtime ,benefits, health insurance, pensions, families and will never sue or make a workers comp claim. I know you won’t post this but it needs to be said. Stop pretending that you care about safety inclusion etc when the real goal is free (almost) labor